Introduction of Energy Efficient Refrigeration System in Industrial Cold Storage

- Representative Participant

- KANEMATSU CORPORATON

Partner Participant: Better Foods Co., Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

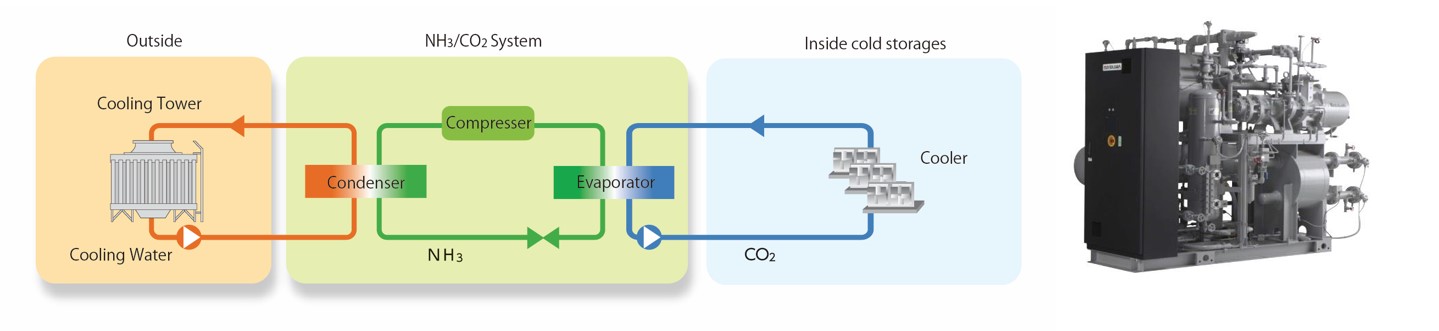

Food industry is a major industrial sector in Thailand, and Better Foods plants to install a refrigeration system with natural refrigerants (NH3/CO2) in their new cold distribution center. This refrigeration system employs an “indirect cooling method,” which uses ammonia to cool CO2 and then CO2 is transported to a cooler in a cold storage. By this method, ammonia is contained in the machine room alone and only CO2 is circulated in the cooler, ensuring the occupational safety. Also, the system uses approximately 20% less energy in comparison to conventional HFC refrigerators.

Expected GHG Emission Reductions

293 tCO2-eq./year

Emission reductions

= Reference emission (RE) – Project emission (PE)

- RE: Power consumption of project system is multiplied by ratio of COPs for reference/project systems and grid emission factor

- RE systems : -25℃ system = NH3 flooded, pump circulation; 0 ℃・5℃ = NH3 /brine

- PE: Power consumption of project system is multiplied grid emission factor

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM011 Ver1.0 | Installation of Energy-efficient Refrigerators Using Natural Refrigerant at Cold Storage | KANEMATSU CORPORATION |