Introduction High Efficiency Looms in Weaving Mill

- Representative Participant

- Nisshinbo Textile Inc.,

Partner Participant: NIKAWA TEXTILE INDUSTRY

Registered

Active

Outline of GHG Mitigation Activity

The proposed project aims to reduce electricity consumption and GHG emission by upgrading to air-saving looms at textile factory in Indonesia.

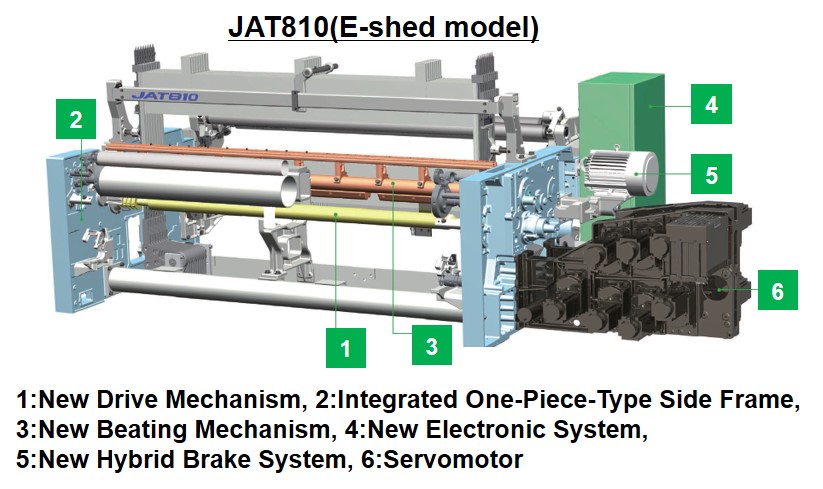

This Air Jet Loom JAT810 made by Toyota Industries Corporation has original air-saving technology to reduce air consumption for weft insertion more 20% than the conventional model. In addition, we will introduce E-shed which is the ultimate shedding device. Fabrics that had been highly challenging to weave can now be woven at high speed.

Expected GHG Emission Reductions

430 tCO2-eq./year

= Reference Emissions − Project Emissions

= 2,151.17 [tCO2/year] − 1,720.94 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM011 Ver1.0 | Installation of energy saving air jet loom at textile factory | Toray Industries Inc. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID020 | Introduction of High-Efficiency Looms in Weaving Mill | 03 Sep 19 |