Energy Saving in Industrial Wastewater Treatment System for Rubber Industry

- Representative Participant

- EMATEC:Environmental Management and Technology Center

Partner Participant: P.T. Aneka Bumi Pratama

Not registered

Active

Outline of GHG Mitigation Activity

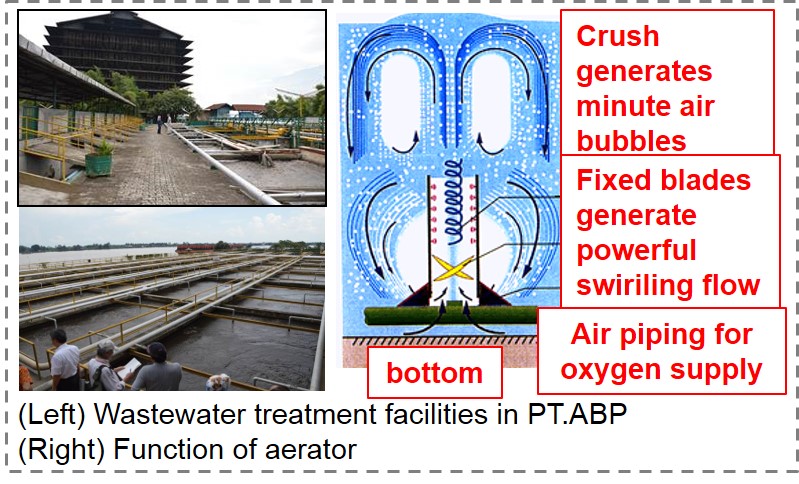

(1) This project aims to reduce electricity consumption in blower at industrial wastewater treatment facility in PT. ABP (Aneka Bumi Pratama), crumb rubber producer in Palembang city, by replacing existing diffuser to aerator.

(2) Both Diffuser and aerator is an aeration device for wastewater treatment but principle is different. Aerator can reduce BOD more efficiently than diffuser and needs less air pressure from blower. Less air pressure contributes to reduce electricity consumption as well as CO2 emissions from electricity.

Expected GHG Emission Reductions

403 tCO2-eq./year

Reference CO2 emissions: 1,485 [tCO2/year]

Project CO2 emissions: 1,082 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM024 Ver1.0 | Replacement of diffuser with aerator in aeration pond | Environmental Management and Technology Center (EMATEC) |