Installation of High Efficiency Kiln in Sanitary Ware Manufacturing Factory

- Representative Participant

- TOTO Ltd.

Partner Participant: TOTO Vietnam Co., LTD.

Not registered

Active

Outline of GHG Mitigation Activity

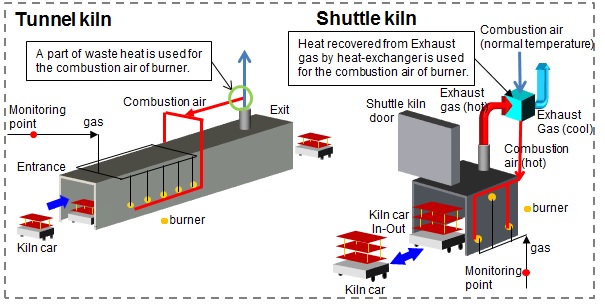

Two High Efficiency kilns (tunnel, shuttle) are installed in a new sanitary ware manufacturing factory in Thang Long Industrial Park II in the suburbs of Hanoi city. The tunnel kiln has a heat recovery system in products cooling stage and the shuttle kiln is equipped with a heat-exchanger for the heat recovery from exhaust gas, reducing usage amount of fuel gas. Maximum energy-saving amount through this function is up to 30%.

Expected GHG Emission Reductions

311 tCO2-eq./year

Tunnel kiln: 302 [tCO2/year]

Shuttle kiln: 9.8 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| VN_AM010 Ver1.0 | Introduction of tunnel and/or shuttle kiln with waste heat recovery system | NTT DATA INSTITUTE OF MANAGEMENT CONSULTING, INC. |