Introduction of High-efficiency Boiler System to Rubber Belt Plant

- Representative Participant

- Bando Chemical Industries, Ltd.

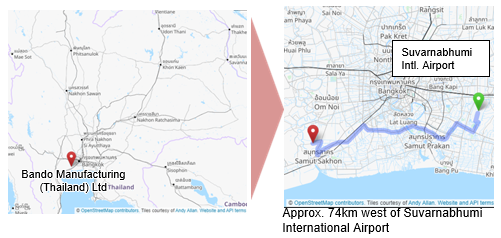

Partner Participant: Bando Manufacturing (Thailand) Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

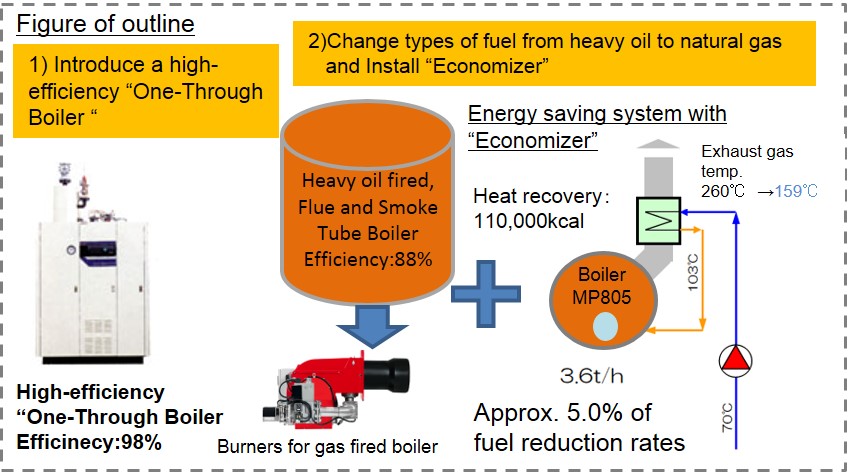

By introducing a new high-efficiency boiler and changing fuel of current flue and smoke tube boilers in rubber belt plant, this project reduces energy consumption and CO2 emission.

1)Introduce a “One-Through Boiler “ with 98% high efficiency.

2)Change boiler fuel types from heavy oil to natural gas which has smaller CO2 emission factor and increase efficiency from 88% to 93% by adding “Economizer” to current three boilers.

Expected GHG Emission Reductions

3,060 tCO2-eq./year

= Reference emissions − Project emissions

= 9,738 [tCO2/year] − 6,678 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM010 ver1.0 | Energy Saving by Introduction of High Efficiency Once-through Boiler and Installation of Economizer into Existing Boiler, Version 01.0 | Nippon Koei Co., Ltd. |