Introduction of 8.8MW Power Generation System by Waste Heat Recovery for Cement Plant

- Representative Participant

- Global Engineering Co., Ltd.

Outline of GHG Mitigation Activity

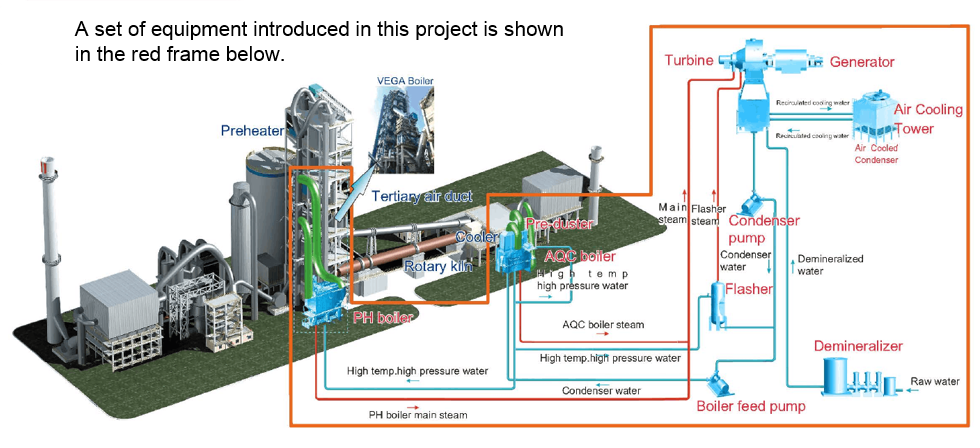

Shwe Taung Cement installs a waste heat recovery power generation (WHRPG) system for their cement factory located in Mandalay, which produces 1,500 ton/day of clinker from the existing line and 4,000 ton/day from a new line. This project contributes to mitigating power shortage in Myanmar, and to the CO2 emission reduction by reducing the consumption of natural gas that is a major source of energy in the country.

This WHRPG system consists of an air quenching cooler (AQC) boiler and a latest preheater (PH) boiler which recovers waste heat and converts into power more efficiently.

All the electricity generated from the project is self-consumed at the factory.

Expected GHG Emission Reductions

19,209 tCO2-eq./year

= Reference CO2 emission-Project CO2 emission

- Reference CO2 Emission

= Net avoided electricity [MWh/y] x Emission Factor [tCO2/MWh]

- Project CO2 emission = 0 tonCO2/y

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| MM_AM005 ver1.0 | Power Generation by Waste Heat Recovery in Cement Industry | Institute for Global Environmental Strategies |