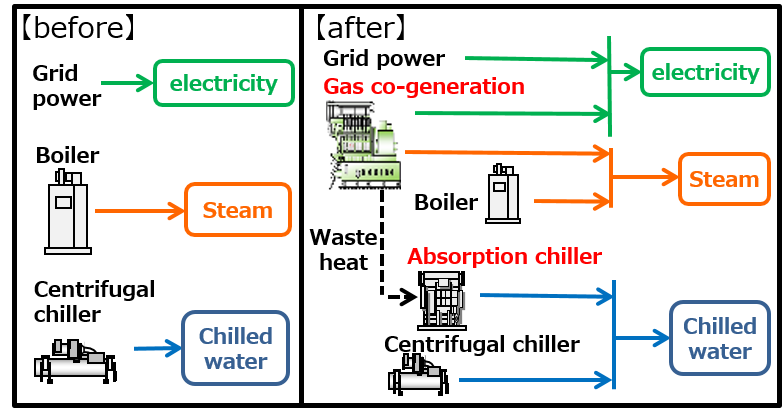

Introduction of Gas Co-generation System and Absorption Chiller to Fiber Factory

- Representative Participant

- Kansai Electric Power Co., Inc.

Outline of GHG Mitigation Activity

This project reduces CO2 emissions by introducing gas co-generation system (5 MW class x 2set) and absorption chiller (800 USRT class) to fiber factory.

These gas co-generation system and absorption chiller contribute to energy saving and cost reduction, and can improve reliability for power supply.

Expected GHG Emission Reductions

16,158 tCO2-eq./year

=①Reference emissions – ②Project emissions

①Reference emissions = (Project electricity supply × CO2 emission factor of the grid) + (Project heat supply ÷ efficiency of reference boiler × CO2 emission factor of natural gas) + (Project removed heat ÷ COP of reference centrifugal chiller × CO2 emission factor of the grid)

②Project emissions = Project fuel consumption × CO2 emission factor of natural gas

Site of JCM Project

Bangpa-in Industrial Estate, Bangpa-in, Ayutthaya 13160, Thailand

60km north from Bangkok