Introduction of Energy Saving Equipment to Brewery

- Representative Participant

- Sapporo International Inc.

Outline of GHG Mitigation Activity

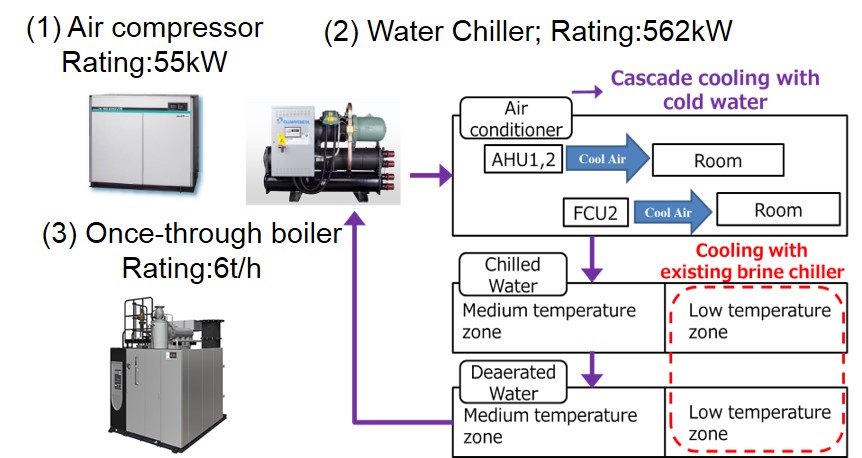

Sapporo Group’s Vietnam branch (Sapporo Vietnam Limited.) introduces highly-efficient and energy-saving equipment together with the expansion of production facilities in Long An brewery. This project reduces electricity and LPG consumption by introducing air compressor, cold water chiller and once-through boiler (LPG). This project reduces the percentage of unloads as well as the frequency of starts / stops and improves the performance of each individual unit. A cascade cooling system is built by the cold water chiller.

Expected GHG Emission Reductions

111 tCO2-eq./year

Air compressor: 18.3 [tCO2/year]

= (RE electricity consumption − PJ electricity consumption) × EFel

= (Electricity required ÷ SP of current equipment × (SPRE − SPPJ)) × EFel

Cold water chiller: 13.6 [tCO2/year]

= (RE electricity consumption − PJ electricity consumption) × EFel

= (Refrigeration capacity required × (1 ÷ COPRE − 1 ÷ COPPJ)) × EFel

Once-through boiler: 79.3 [tCO2/year]

= (RE LPG consumption − PJ LPG consumption) × EFlpg

= (RE LPG consumption

− RE LPG consumption × ηRE ÷ ηPJ × ORPJ

+ RE LPG consumption × (1 − ORPJ)) × EFlpg

RE: Reference, PJ: Project,

EFel: Grid emission factor, EFlpg: LPG emission factor,

SP: Specific power of air compressor,

COP: Coefficient of performance of chiller,

η: Boiler efficiency, OR: Operation rate