Introduction of High Efficiency Chilled Water Supply System in Milk Factory

- Representative Participant

- TEPIA Corporation Japan Co.,Ltd.

Partner Participant: CP-Meiji Co., Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

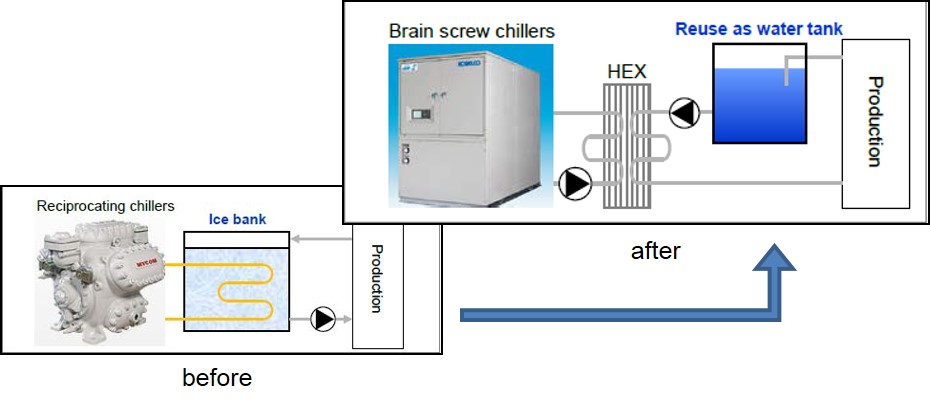

Renewal of cold water supply system by installation of high efficiency chiller to the manufacturing process in major food manufacturing plant in Thailand.

The updated system achieves optimal thermal efficiency by replacing existing reciprocating chiller with high efficiency water-cooled screw chiller, along with introducing a heat exchanger.

Expected GHG Emission Reductions

941 tCO2-eq./year

= (Reference CO2 Emission)

− (Project CO2 Emission)

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM013 Ver1.0 | Energy Saving by Introduction of High Efficiency Screw Chiller for freezing and refrigeration | Tepia Corporation Japan. CO., Ltd. |