Introduction of Energy Saving Brewing Systems to Beer Factory

- Representative Participant

- Kirin Holdings Company, Limited.

Partner Participant: Myanmar Brewery Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

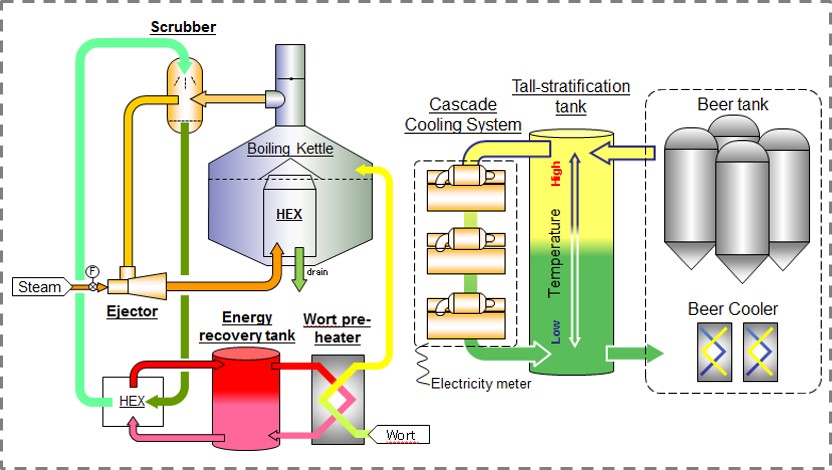

With a producing system expansion plan of the beer factory in Myanmar, an introduction of the high efficiency equipment in the process for brewing beer realizes energy saving and reduces CO2 emissions.

In the process for boiling wort, heat recovery system, recovers steam and reuse it as heat, is installed and one of the existing furnace smoke tube boiler are replaced 7 one through boilers.

In the process for cooling, tall-stratification tanks with cascade cooling system (High Efficiency Chiller System) are installed.

Expected GHG Emission Reductions

2,841 tCO2-eq./year

Heat recovery system:

997 [tCO2/year]

One through boiler:

1,029 [tCO2/year]

High Efficiency Chiller System:

815 [tCO2/year]