Introduction of High Efficiency Electrolyzer in Chlorine Production Plant

- Representative Participant

- Kanematsu Corporation

Outline of GHG Mitigation Activity

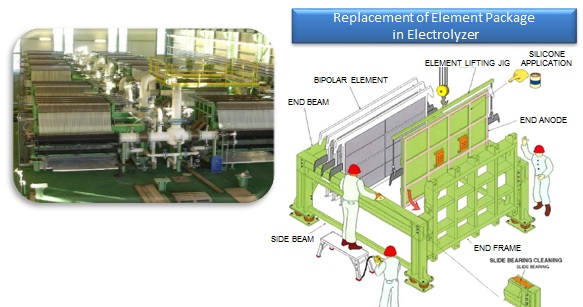

JANA produces chlorine and caustic soda, which consumes much electrical power. This project is intended to replace the existing elements of ion exchange membrane (IEM) brine electrolyzers to the latest high efficiency model which will contribute to reducing energy consumption.

The bipolar electrolyzer consists of multiple elements, which have cathode and anode chambers, and IEMs are installed betweeneach element. The high efficiency model is designed to optimize elements’ inner structures and electrode shape, reducing resistance (lowering the voltage) of various components and preventing the mechanical damage for IEM, and thus have achieved lower power consumption.

Expected GHG Emission Reductions

3,289 tCO2-eq./year

Emission reductions are calculated by comparing 2 electrolyzers of different manufactures.

Emission reductions

= Reference emission reductions (RE) – Project emission reductions (PE)

RE: Specific GHG emissions (non-efficiency model) x amount of chlorine gas produced

PE: Specific GHG emissions (high efficiency model) x amount of chlorine gas produced

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| SA_AM001 Ver1.0 | Introduction of High Efficiency Electrolyzer in Chlor-Alkali Processing Plant | Thyssenkrupp Uhde Chlorine Engineers (Japan) Ltd.; Kanematsu Corporation |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| SA001 | Introduction of High Efficiency Electrolyzer in Chlor-Alkali Production Plant | 13 Jul 18 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| SA001 | 25 Jan 17 - 31 Aug 18 | 5 Mar 20 | 5,300 |