Introduction of High Efficient Old Corrugated Cartons Process at Paper Factory

- Representative Participant

- Nomura Research Institute, Ltd.

Outline of GHG Mitigation Activity

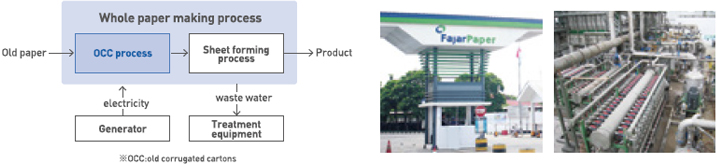

The study plans to target reductions of energy use in the corrugated carton production process in Indonesia. A corrugated carton production process consists of two main processes, an old corrugated cartons process and a sheet forming process.

This project aims to reduce power use in the former process.

To realize the reduction of power use (about 10%) per ton produced and contribute to CO2 reduction by introducing Japanese technology for a high-efficient system and OCC process to a newly built factory in Fajar of Indonesia (holding the second largest manufacturing share).

In the OCC process, the sheet-paper material is made by removing foreign substances using multiple machines from ground and then liquefied old paper with water.

This process is composed of about 30 units of machinery. The high efficiency of the machinery makes the motor power requirement of each unit small, realizing an energy saving of approximately 10%.

Expected GHG Emission Reductions

Approx. 14,884.6 tCO2/year

- Methodology

ER = RE – PE

= [(Reference OCC process electricity consumption rate (MWh/ton)) x (Project OCC process generation amount (ton/year)) – (Project OCC Process electricity consumption amount (MWh/year)] x (Electricity CO2 emission factor (tCO2/MWh)) - Reference and Project emission amount estimated value

RE= 83,938.6 t/year

PE= 69,054.0 t/year

Site of JCM Project

Bekasi, West Java, Indonesia