Improvement of Combustion Method and Furnace Shapes in Flat Glass Production Melting Furnace

- Representative Participant

- AGC Inc.

Outline of GHG Mitigation Activity

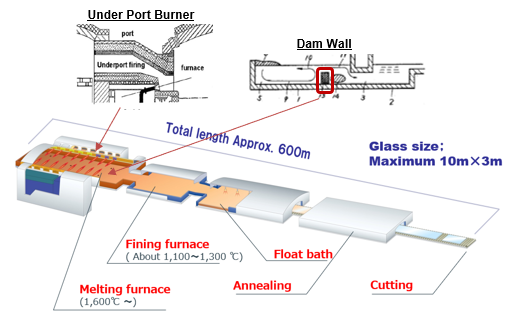

In a flat glass production process, a large amount of fossil fuel is consumed mainly in the melting process of raw materials. Therefore, improvement in this energy efficiency greatly contributes to reduction of greenhouse gas (GHG) emissions.

In this project, a furnace structure is improved to save energy consumption by the following two changes.

A. Change in combustion method:

Through port burner ⇒ Under port burner

B. Change in the melting tank floor structure:

Flat structure ⇒ Dam wall structure

Expected GHG Emission Reductions

5,747 tCO2-eq./year

= (Reference CO₂ emissions)

- (Project CO₂ emissions)

・ Reference CO₂ emissions

= Glass Drawing Weight [ton] x Unit fuel consumption before project [Nm3/ton] x Emission factor [tCO2/Nm3]

・ Project CO₂ emissions

= Glass Drawing Weight [ton] x Unit fuel consumption during project [Nm3/ton] x Emission factor [tCO2/Nm3]

Site of JCM Project