Energy Saving by Introducing High Efficiency Autoclave to Infusion Manufacturing Factory 2

- Representative Participant

- Otsuka Pharmaceutical Factory, Inc.

Outline of GHG Mitigation Activity

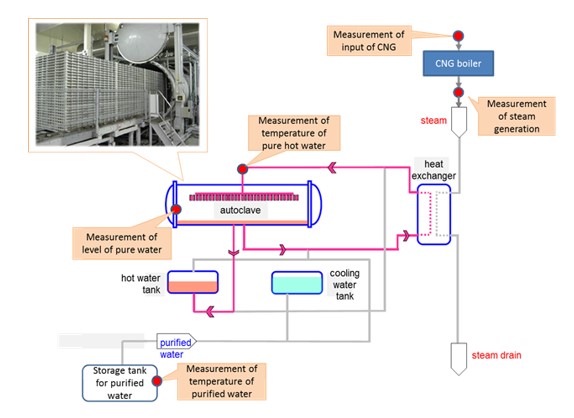

At a new infusion manufacturing factory in the existing infusion manufacturing base of PT. Otsuka Indonesia under the Otsuka Group, a new type of high efficiency autoclave, which fulfills the Good Manufacturing Practice (GMP) and realizes energy and resource saving, is introduced to contribute to the solution of global environmental issues as well as to assure the safety of pharmaceutical products.

Since the hot water to be injected into the autoclave is maintained at a high temperature, both the amount of steam charged in a batch unit and consumption of natural gas (CNG) required for steam generation are reduced. In addition, pure water used in the sterilization process is reused, so that the amount of pure water is also greatly saved.

Expected GHG Emission Reductions

9,330 tCO2-eq./year

=(Reference CNG consumption volume

– project CNG consumption volume) X Emission factor of CNG.

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM028 | Energy saving by introducing waste hot water recovery system to autoclave in infusion manufacturing process line | Otsuka Pharmaceutical Factory, Inc. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID034 | Energy Saving by Introducing High Efficiency Autoclave to Infusion Manufacturing Factory 2 | 18 Dec 24 |