Introduction of Energy Saving Equipment to Automotive Wire Production Factory

- Representative Participant

- YAZAKI PARTS CO., LTD.

Partner Participant: YAZAKI EDS VIETNAM Co., LTD.

Registered

Credit issued

Active

Outline of GHG Mitigation Activity

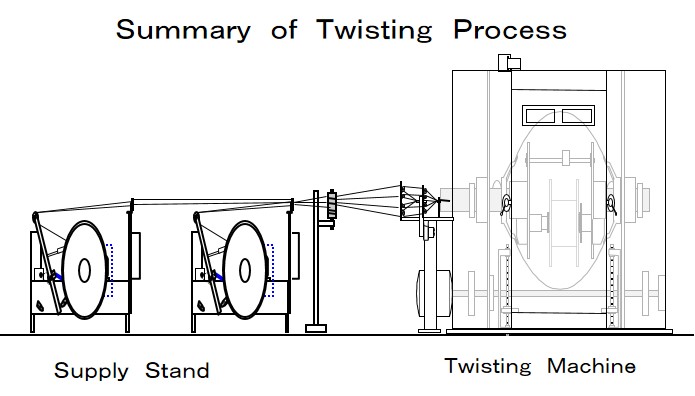

This project reduces electric power consumption by introducing high-efficient wire stranding machines.

The new machines contribute to the reduction of GHG emission by energy-saving measures, such as reinforced frames, friction reduction mechanism and installation of smaller, lightweight parts and high-efficient motor.

Expected GHG Emission Reductions

591 tCO2-eq./year

= (Reference CO2 emissions) − (Project CO2 emissions)

Reference CO2 emissions: 1,751.0 [tCO2/year]

Project CO2 emissions: 1,159.6 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| VN_AM014 Ver1.0 | Introduction of energy efficient wire stranding machines to automotive wire production factory | YAZAKI Parts Co.,Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| VN014 | Introduction of high-efficient wire stranding machines to the factory of YAZAKI EDS VIETNAM Co., LTD. | 28-May-19 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| VN014 | 01 Nov 18 - 30 Jun 19 | 31 Oct 24 | 379 |