Introduction of Heat Recovery Heat Pumps to Food Processing Factory

- Representative Participant

- CPF JAPAN CO., LTD.

Partner Participant: CPF (Thailand) Public Company Limited

Registered

Active

Outline of GHG Mitigation Activity

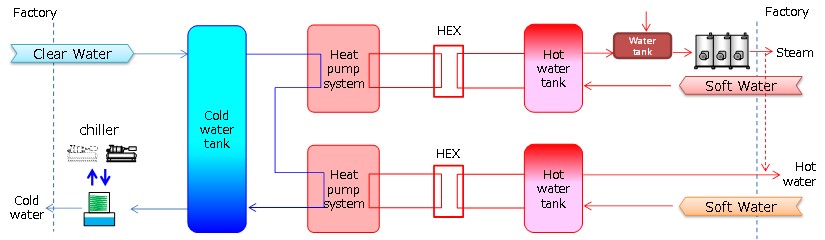

This project reduces CO2 emission by introducing a simultaneous heating & cooling heat pump to the meat processing plant to reduce power for chiller.

By preheating the boiler feed water with the heat pump, the project reduces the heating load of the boiler and the fuel consumption.

On the other hand, by precooling the chiller feed water with the heat pump, the project reduces the cooling load and the power consumption of the chiller.

Expected GHG Emission Reductions

942 tCO2-eq./year

= Project CO2 Emission – Reference CO2 Emission

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM008 Ver1.0 | Introducing heat recovery heat pumps with natural refrigerants for the food manufacturing industries | Mitsubishi UFJ Morgan Stanley Securities Co., Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| TH008 | Introduction of Heat Recovery Heat Pumps to a Chicken Slaughtering Plant in Thailand | 20 Sep 21 |