Introduction of High-efficiency Once-through Boiler in Instant Noodle Factory

- Representative Participant

- Acecook Co.,Ltd.

Partner Participant: Acecook Myanmar Co.,Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

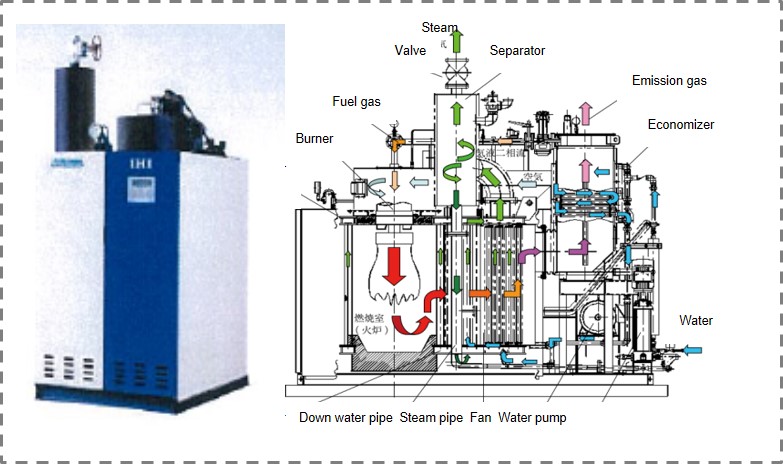

For energy saving, once-through boiler of high-efficiency and low air pollutant emission type is installed to supply steam in an instant noodle factory. Fuel consumption and emission of CO2 and air pollutant is reduced by the project boiler.

The project boiler has high energy saving characteristics with four positions control (at 100%, 65%, 25%, 0% load) and economizer.

Expected GHG Emission Reductions

674 tCO2-eq./year

ß(FCRB – FCPB) x EF

=( PB Efficiency / RB Efficiency x FCPB – FCPB)×EF

FCPB: fuel consumption of project boiler

FCRB: fuel consumption of reference boiler

PB: project boiler

RB: reference boiler

EF: emission factor

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| MM_AM003 ver1.0 | Energy Saving by Introduction of High Efficiency Once-through Boiler | Nippon Koei Co., Ltd. |