Energy Saving for Air-Conditioning in Tire Manufacturing Factory with High Efficiency Centrifugal Chiller

- Representative Participant

- Inabata & Co., Ltd.

Outline of GHG Mitigation Activity

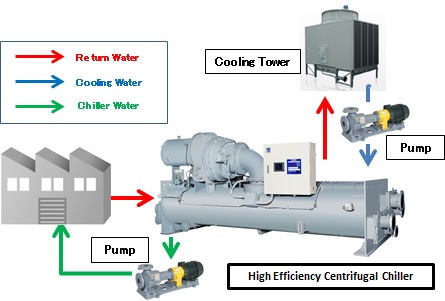

Air-conditioning is indispensable in maintaining the quality control of the product and working environment in the Tire Manufacturing Factory. The air-conditioning system operates long time and causes large power consumption. An introduction of the high efficiency Centrifugal Chiller realizes energy saving of the air-conditioning and reduces CO2 emissions.

The Centrifugal Chiller adopts a high-performance compressor (two stage compressor), which miniaturizes the compressor and reduces electric power consumption. In addition, the chiller adopts refrigerant HFC245fa which has higher cycle performance and energy efficiency than conventional refrigerant HFC134a.

Expected GHG Emission Reductions

208 tCO2-eq./year

Reference Emissions = EF×EC×(COPPJ/COPRE)

Project Emissions = EF×EC

Emission reductions = RE-PE

EF :CO2 Emission factor =0.5113(tCO2/MWh)

EC :Power consumption of project chiller (MWh)

COPPJ : COP of project chiller

COPRE : COP of reference chiller

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM005 Ver2.0 | Energy Saving by Introduction of High Efficiency Non-Inverter Type Centrifugal Chiller | Nippon Koei Co., Ltd |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| TH007 | Energy Saving for Air conditioning in Tire Manufacturing Factory with High Efficiency Centrifugal Chiller | 17 Jun 22 |