Energy Saving for Semiconductor Factory with High Efficiency Centrifugal Chiller and Compressor

- Representative Participant

- Sony Semiconductor Manufacturing Corporation

Outline of GHG Mitigation Activity

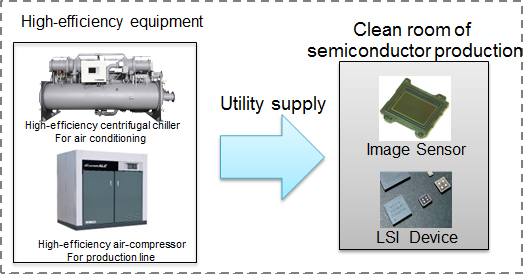

The project aims to reduce environmental impact, which is mainly carbon dioxide emissions from energy use through replacing existing equipment with better energy-saving equipment, high-efficiency centrifugal chiller and air-compressor, in the clean room of semiconductor plant in Thailand, Bangkadi Industrial Park.

High-efficiency equipments also control the accurate temperature and humidity in the clean room, work well. The project contributes to the spread of more efficient technology in Thailand.

Expected GHG Emission Reductions

365 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

− (Project CO2 emissions) [tCO2/year]

Air-compressor: 51 [tCO2/year]

Reference CO2 emissions: 731.1 [tCO2/year]

Project CO2 emissions: 679.6 [tCO2/year]

Centrifugal Chiller: 314 [tCO2/year]

Reference CO2 emissions: 4,202.0 [tCO2/year]

Project CO2 emissions: 3,887.7 [tCO2/year]

Site of JCM Project

Sony Device Technology(Thailand) Bangkadi Plant(Bangkadi Industrial Park)

Assembly & Test of LSI and Image Sensor

Production plan is image sensor for digital single-lens reflex camera, and LSI device for smartphone.

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM002 Ver2.0 | Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor | Sony Corporate Services (Japan) Corporation |

| TH_AM003 Ver1.0 | Energy Saving by Introduction of High Efficiency Inverter Type Centrifugal Chiller | Sony Corporate Services (Japan) Corporation |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| TH004 | Energy Saving for Semiconductor Factory with High Efficiency Centrifugal Chiller and Compressor | 20-Apr-18 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| - | TH004 | 01 Apr 17 - 31 Dec 17 | 2 Aug 19 | 115 |