Installation of High Efficiency Loom at Weaving Factory

- Representative Participant

- Toyota Tsusho Corporation

Outline of GHG Mitigation Activity

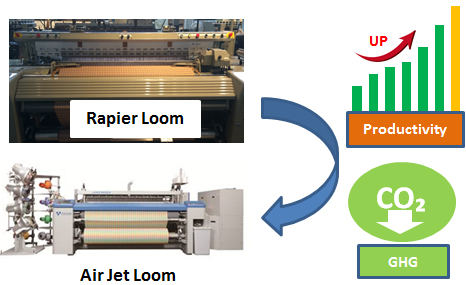

The textile industry is a key industry in Bangladesh, accounting for more than 80% of the total exports. This project introduces air jet looms at a weaving factory, which can reduce energy consumption and increase productivity at the same time.

Currently, rapier looms are widely used in Bangladesh and many of them are secondhand. Compared to the rapier looms, air jet looms introduced in this project have 1.8 times higher productivity and 15% higher energy efficiency, which means approximately 53% energy efficient in terms of unit per area of fabric produced.

The air jet looms are environmentally sound not causing problems such as noise and waste water treatment.

Expected GHG Emission Reductions

437 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

− (Project CO2 emissions) [tCO2/year]

Reference CO2 emissions: 1,943.1 [tCO2/year]

Project CO2 emissions: 1,505.9 [tCO2/year]

Site of JCM Project

Dhaka, Bangladesh

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| BD_AM003 Ver1.0 | Energy efficiency improvement through the introduction of energy efficient air jet looms in textile industry | Toyota Tsusho Corporation; Mitsubishi UFJ Morgan Stanley Securities Co., Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| BD003 | Installation of High Efficiency Loom at Weaving Factory | 04 Apr 19 |