Contribution towards SDGs through JCM Model Projects(AAIC Japan Co., Ltd.)

Selected Year: 2022

Host Country: Kenya

Project Title: Introduction of 3.1MW Rooftop Solar Power System to Food Processing Facilities

Representative Participant: AAIC Japan Co., Ltd.

Partner Participant: Unga Holdings Limited / Unga Limited / Unga Farm Care (E.A.) Limited

(Project Information URL)https://gec.jp/jcm/projects/22pro_ken_01/

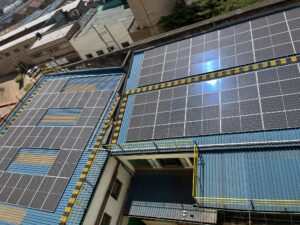

▲Solar panels installed at UNGA’s feed processing facility in Nakuru County

【Project Summary: Solar Power Equipment to Be Installed on Factory Rooftop by Utilizing the JCM Project Financially supported by MOEJ】

This project involves the installation of a total of 3.1 MW of solar power systems across four grain milling facilities and three feed processing facilities located in Nairobi County, Eldoret County, and Nakuru County in the Republic of Kenya. By generating and consuming electricity on-site, the project reduces reliance on grid electricity and contributes to the reduction of greenhouse gas (GHG) emissions.

【Motivation and background for taking on the SDGs: A Business Rooted in the Vision of ‘Taking Responsibility for the Future and the Environment】

UNGA Group has embraced the philosophy of “taking responsibility for the future and the environment” and has been actively promoting the Sustainable Development Goals (SDGs) since around 2020. According to Mr. Anton, who kindly participated in this interview, the company began its sustainability journey by gaining a basic understanding of carbon footprints and assessing water usage and waste emissions at its factories. Building on this foundation, UNGA introduced energy-saving measures at all of its facilities, which also involved phasing out outdated equipment as part of process improvements. The economic benefits derived from these SDG initiatives have also played a significant role in motivating the company to continue its efforts.

【SDGs-related initiatives: From energy conservation to greywater utilization】

Each factory is engaged in a variety of sustainability efforts. Key initiatives include:

- Promoting the use of renewable energy at all factory sites.

- Installing underground tanks to collect rainwater, which is reused as greywater for toilets and irrigation purposes.

- Monitoring waste disposal and the volume of defective products being reworked, and introducing process improvements to minimize waste.

- Partnering with a local Kenyan company to collect and recycle vinyl packaging materials generated at the company’s facilities.

【Business and Stakeholder Benefits from SDG Initiatives: Driving Cost Reductions through Sustainability】

UNGA realizes that its SDG initiatives have resulted in significant cost savings, which have enhanced the company’s overall competitiveness. As such, the company considers its own business operations and shareholders to be the primary beneficiaries of these efforts. Moreover, the reduction in energy costs through the adoption of energy-efficient equipment has helped offset expenses related to landfill use and waste disposal.

▲Solar panels installed at the UNGA factory near Nairobi

【Future Challenges for SDG Initiatives: Promoting the Use of Renewable Energy】

UNGA has set a target of generating 28% of its total energy consumption from renewable sources. However, progress has been uneven across its factories, with some being slower to adopt solar power generation (PV). Additionally, the impact of recent climate conditions—such as a prolonged rainy season and lower-than-usual temperatures in 2024—has hindered solar output, resulting in a current renewable energy ratio of only 9%. The company recognizes that further efforts are necessary to reach its target.

In addition, UNGA has been working on the SDGs, so relatively easy measures are already in place.However, economic barriers to initiatives such as energy-saving measures are expected to be a major challenge in the future due to the impact of rising prices.

【About the JCM Project financially supported by MOEJ】

The JCM Project financially supported by the MOEJ, played a crucial role in making this project a reality. Without this support, it would have been difficult to carry out the project as planned or to introduce equipment that exceeded the originally envisioned specifications. For this reason, UNGA expresses its deep appreciation for the support provided through the JCM Project.