Contribution towards SDGs through JCM Model Projects(Osaka Gas Co., Ltd.)

Selected Year: 2021

Host Country: Thailand

Project Title: Introduction of High Efficiency Once Through Boiler to Garment Factory

Representative Participant: Osaka Gas Co., Ltd.

Partner Participant: OSAKA GAS (THAILAND) CO., LTD. and Parfun Textile Co., Ltd.

(Project Information URL)https://gec.jp/jcm/projects/21pro_tha_01/

Project Overview:

The garment factory requires a large amount of heat during the dyeing and drying processes.

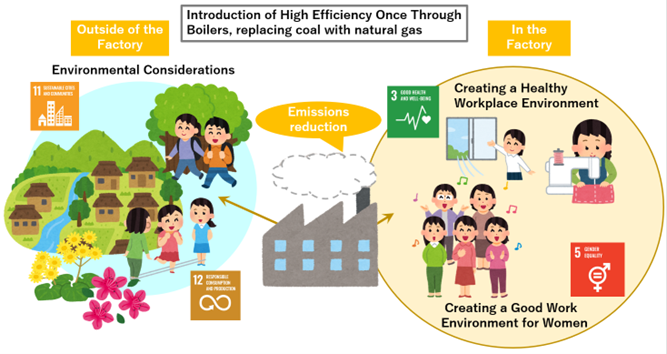

This project aims to reduce greenhouse gas (GHG) emissions by replacing the existing water tube boilers with high-efficiency once-through boilers at the garment factory of Parfun Textile Co., Ltd. in Nakhon Pathom province, converting the fuel from coal to natural gas.

The use of steam is essential in the dyeing and drying processes in garment factories. Until now, coal combustion water tube boilers have been used to produce steam at the factory of Parfun Textile Co., Ltd. in Nakhon Pathom province, where there are many areas where natural gas pipelines have not been laid, and factories in these areas mainly use coal or oil as fuel. However, with the global trend towards decarbonization, Parfun Textile Co., Ltd. became increasingly aware of the importance of low-carbonization and decarbonization of its products, and it was around that time Parfun Textile Co., Ltd. received a proposal from OSAKA GAS (THAILAND) CO., LTD. to introduce high efficiency once-through boilers at their factory, converting to natural gas, a low-carbon fuel. Even though the price of fuel would increase, Parfun Textile Co., Ltd. decided to take a step forward to replace the coal-fired water tube boilers with natural gas-fired once-through boilers to fulfil its corporate social responsibility by taking environmental measures and contributing to society, and to contribute to low carbon emissions in Thailand and the world.

【Motivation and background behind the contribution towards SDGs】

Environmental considerations for the surrounding area of the factory

- The production of garments requires a lot of energy, so the environmental impact cannot be ignored.

- The impact on the surrounding environment is a matter of particular concern. There were complaints from neighbors about the odor caused by coal fuel, but after the introduction of the natural gas-fired once-through boilers, no complaints have been received.

- The switch to natural gas-fired once-through boilers has resulted in cleaner soot emissions and reduced the impact on the surrounding environment.

Workplace environment

- 95% of the employees working at Parfun Textile Co., are women.

- Efforts are made to create a good work environment for women.

- The company has struggled with how to keep the workplace environment clean, as the yards where coal is stored can be dusty.

The use of natural gas eliminates the need for coal storage, which contributes to keeping the factory clean at all times.

【Initiatives of Parfun Textile Co., Ltd.】

【Benefits gained through the SDGs initiatives】

Contribution to the low carbonization of products

- Parfun Textile Co., Ltd. has established initiatives and targets for reducing CO2 emissions from the energy used to manufacture its garment products, and regularly reports to its business partners on the implementation plan and results in achieving these targets, which is highly appreciated.

- Parfun Textile Co., Ltd. feels that it is contributing to global environmental protection through significantly reducing the carbon footprint of its products by converting coal fuel to natural gas.

(Future prospects of Parfun Textile Co., Ltd.)

- We would like to consider not only low and decarbonization for heat demand, but also decarbonization for electricity demand.

- We believe that continuous environmental measures are essential as an important mission of the company and are in the process of installing a solar power generation system as our next project.

(Future prospects of the Representative Participant, Osaka Gas Co., Ltd.)

- We would like to actively engage in introducing rooftop solar systems, etc. to our factories around the world.