Efficiency Improvement of Co-generation System by Installation of Heat Exchanger in Fiber Factory

- Representative Participant

- NIPPON STEEL ENGINEERING CO., LTD.

Outline of GHG Mitigation Activity

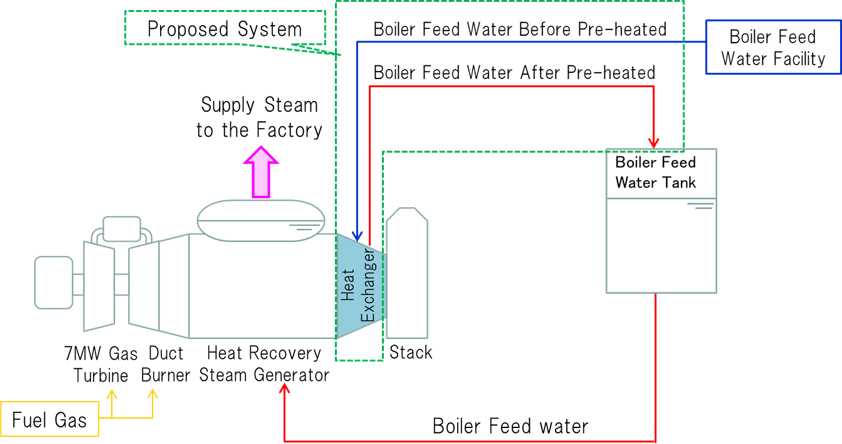

This project aims to efficiently utilize unused thermal energy of the co-generation system to heat boiler feed water. A heat exchanger is additionally installed to the existing co-generation system which is composed of 7 MW gas turbine and heat recovery steam generator equipped with duct burner.

Natural gas fuel used for duct burner is reduced by approx. 4%, by increasing the temperature of boiler feed water by approx. 20 degrees Celsius.

Expected GHG Emission Reductions

359 tCO2-eq./year

= (Reference CO2 Emission) − (Project CO2 Emission)

(Reference CO2 Emission)

= [(BFW temp. after heat recovery) − (BFW temp. before heat recovery)]

× (BFW amount) × (Specific heat of water)

÷ (Boiler efficiency) × (CO2 emission coefficient of fuel)

BFW: Boiler Feed Water

(Project CO2 Emission) = 0

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM018 | Waste heat recovery and utilization by installing heat exchanger to heat recovery steam generator of gas co-generation system | Institute for Global Environmental Strategies (IGES) |