Energy Saving in Acid Lead Battery Factory with Container Formation Facility

- Representative Participant

- Hitachi Chemical Company, Ltd.

Outline of GHG Mitigation Activity

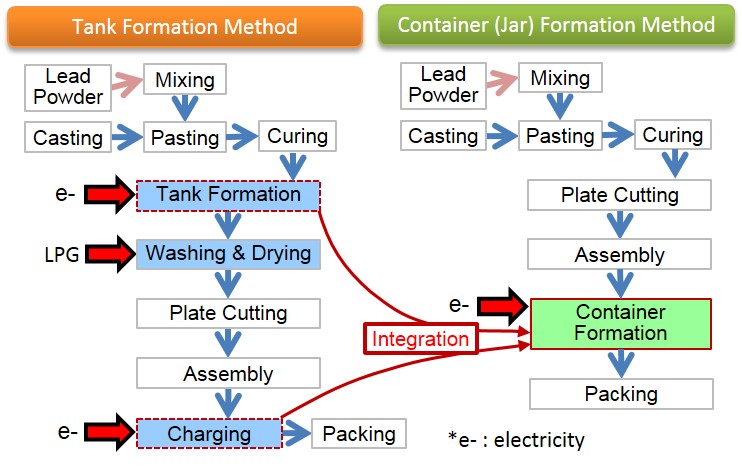

Currently, CSB Battery (Vietnam) manufactures small valve-regulated lead-acid (VRLA) batteries* (so-called sealed battery) with the tank formation method (See the chart below). This project introduces container formation method to some production lines, and about 60% of CO2 from fossil fuel combustion is reduced by integrating formation and charging processes, which consume much of energy in the 11-step battery production, and eliminating a drying process and LPG usage. Furthermore, this new formation method reduces water consumption by removing washing step.

(*Compared to flooded lead-acid battery, it doesn’t need to refill water and is utilized in various ways, such as in uninterruptible power supply (UPS).)

Expected GHG Emission Reductions

3,825 tCO2-eq./year

= Reference emission reductions (RE)

− Project emission reductions (PE)

= 7,293.1 [tCO2/year] − 3,467.4 [tCO2/year]

RE: CO2 emissions from battery production with tank formation method

PE: CO2 emissions from battery production with container formation method

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| VN_AM009 Ver1.1 | Installation of Container Formation Facility at Lead Acid Battery Factory | Hitachi Chemical Co., Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| VN010 | Installation of Container Formation Facility at Lead Acid Battery Factory of Hitachi Chemical Energy Technology (Vietnam) Co., Ltd. | 28 May 2019 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| VN010 | 01 Apr 18 - 30 Jun 19 | 31 Oct 24 | 3,288 |