Introduction of Energy Saving Centrifugal Chillers to Machinery Factory

- Representative Participant

- The Kansai Electric Power Company, Incorporated

Partner Participant: Kansai Energy Solutions (Thailand)

Not registered

Active

Outline of GHG Mitigation Activity

This project reduces energy consumption as well as greenhouse gas (GHG) emissions by introducing module turbo chillers (400USRT x 2 unit) and inverter pumps at a machinery factory.

Module turbo chillers include several compressors for 1 unit, which improve their reliability with high redundancy and maintainability.

Expected GHG Emission Reductions

225 tCO2-eq./year

=①Reference emissions – ②Project emissions

①Reference emissions = (Electricity consumption calculated by COP of reference turbo chiller × CO2 emission factor ofthe grid)

②Project emissions = (Electricity consumption calculated by COP of new turbo chiller × CO2 emission factor of the grid)

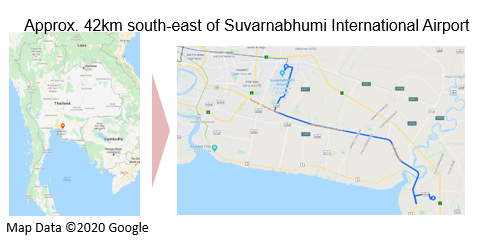

Site of JCM Project