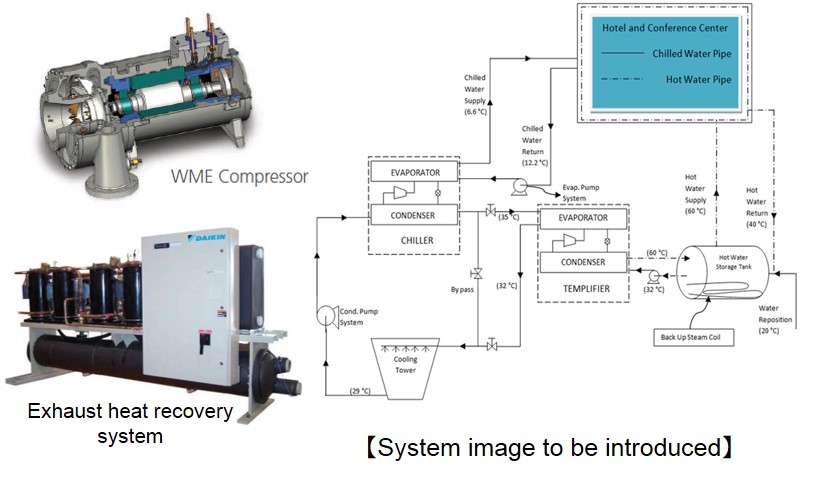

Introduction of the High Efficiency Chiller and the Exhaust Heat Recovery System

- Representative Participant

- NTT Data Institute of Management Consulting, Inc

Outline of GHG Mitigation Activity

This project aims to improve the energy efficiency of a luxury hotel’s air-conditioning system by replacing the existing centrifugal chiller with a high efficiency chiller and existing heavy oil boilers with a water heater utilizing the waste heat from the chiller.

The high efficiency chiller (Daikin WMC400DC) delivers; low operating noise (76dBA), optimized control through digital, easy to maintenance. It enables to improve the energy efficiency of up to 40% compared to a standard centrifugal chiller and restart in as little as 43 seconds after a power restoration.

The high efficiency exhaust heat recovery water heater (Daikin Templifier TGZ060B) can supply hot water and heating, and also be utilized for cooling the cooling tower by combining with the chiller.

Expected GHG Emission Reductions

585 tCO2-eq./year

= Reference CO2 emissions (RE) – Project CO2 emissions (PE)

High efficiency chiller: 160 tCO2/year

RE: 650.6 [tCO2/year]

PE: 490.2 [tCO2/year]

Exhaust heat recovery water heater: 425 tCO2/year

RE: 491.0 [tCO2/year]

PE: 65.2 [tCO2/year]