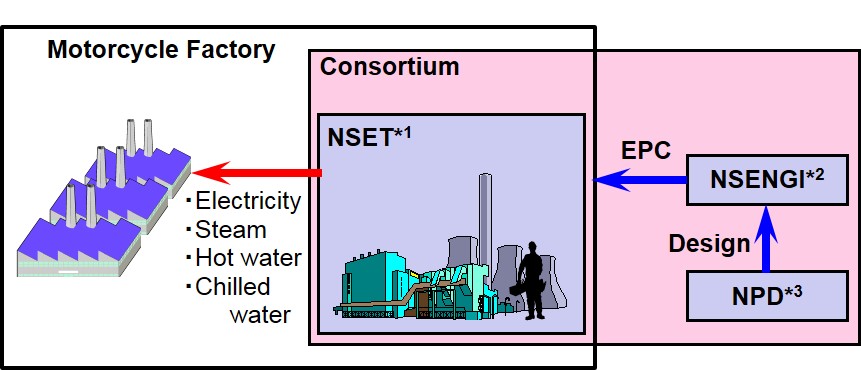

Installation of Co-Generation Plant for On-Site Energy Supply in Motorcycle Factory

- Representative Participant

- Nippon Steel & Sumikin Engineering Co., Ltd.

Outline of GHG Mitigation Activity

A co-generation plant, which mainly consists of a 7MW gas engine and heat recovery steam generator, and high efficiency centrifugal chiller are installed in a motorcycle factory located in a suburb of Bangkok by the local subsidiary (NSET *1) of the Japanese representative company (NSENGI *2) . NSET owns and operate this plant, and supply energy(electricity, steam, chilled and hot water). Therefore, the factory can reduce GHG emission.

Expected GHG Emission Reductions

7,262 tCO2-eq./year

CO2 emission reduction by co-generation + CO2 emission reduction by centrifugal chiller

= [(Project Electricity Generation x Grid Emission Factor) + {(Reference Natural Gas Consumption – Project Natural Gas Consumption) x Natural Gas Emission Factor}] + {(Reference Chiller Electricity Consumption – Project Chiller Electricity Consumption) x Grid Emission Factor}

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM005 Ver2.0 | Energy Saving by Introduction of High Efficiency Non-Inverter Type Centrifugal Chiller | Nippon Koei Co., Ltd |

| TH_AM009 Ver1.0 | Installation of gas engine cogeneration system to supply electricity and heat | Institute for Global Environmental Strategies |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| TH013 | Installation of Co-Generation Plant for On-Site Energy Supply and High Efficiency Non-Inverter Type Centrifugal Chiller in Motorcycle Factory | 17 Jun 22 |