Introduction of High-efficiency Once-through Boiler System in Film Factory

- Representative Participant

- Mitsubishi Chemical Corporation

Outline of GHG Mitigation Activity

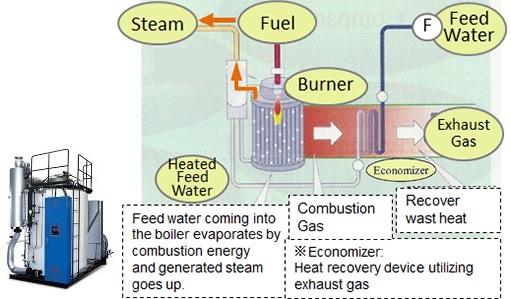

The factory has been using a water tube boiler (oil type) for plastic film production. In this project, a high efficiency one-through boiler (gas type) is introduced for energy saving.

This one-through boiler with PI control better manages the combustion and feed waster supply, which contribute to increased boiler efficiency and stable steam supply. For instance, it can achieve maximum boiler efficiency of 98% (95-97% under practical condition), whereas the efficiency of conventional fire tube boiler and water tube boiler is around 88%. Also, built-in inverters can reduce electricity consumptions.

Expected GHG Emission Reductions

816 tCO2-eq./year

Emission reductions is calculated by estimating the boiler efficiency of 89% for conventional boilers and 93% for project boilers

Fuel consumed for production of 1t of steam(1t/t) x steam produced(t) x emission factor(tCO2/lt) x electricity used x grid emission factor

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM015 Ver1.0 | Energy Saving by Introduction of High Efficiency Once-through Boiler | Nippon Koei Co., Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID021 | Introduction of High-efficiency Once-through Boiler in Film Factory | 31 Oct 19 |