Reducing GHG Emission at Textile Factories By Upgrading to Air-saving Loom

- Representative Participant

- Toray Industries, Inc.

Outline of GHG Mitigation Activity

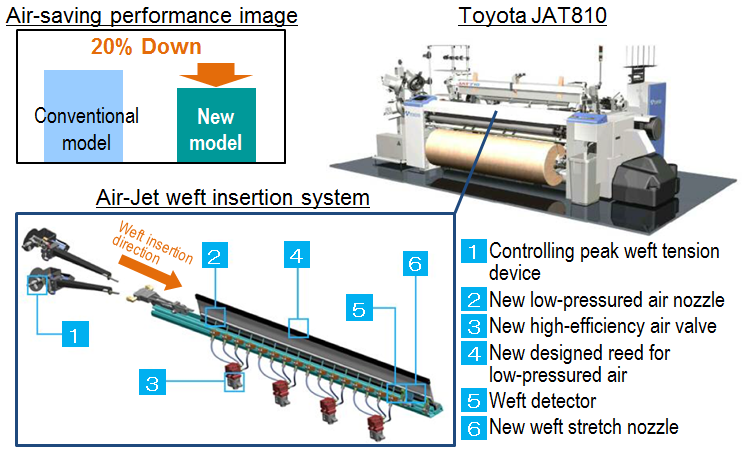

Exporting textiles products from Indonesia is the highest amount in South-eastern Asia. In the project, at 3 sites of textile factory in Indonesia we will upgrade existing weaving looms to total 81 units of the latest air-saving loom(*).

* “Toyota JAT810”

This “JAT810” has original air-saving technology to reduce air consumption for weft insertion more 20% than the conventional model. The effect is not only reducing CO2 emission by saving the power consumption of air-compressors but also reducing the running cost.

Expected GHG Emission Reductions

742 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

− (Project CO2 emissions) [tCO2/year]

Reference CO2 emissions: 3,058.5 [tCO2/year]

Project CO2 emissions: 2,316.2 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM011 Ver1.0 | Installation of energy saving air jet loom at textile factory | Toray Industries Inc. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID015 | Reducing GHG emission at textile factories by upgrading to air-saving loom | 24 Aug 18 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| - | ID015 | 01 Jan 17 - 30 Sep 18 | 10 Jan 20 | 1,244 |