Energy Saving for Air Conditioning & Facility Cooling By High-efficiency Centrifugal Chiller (Suburbs of Dhaka)

- Representative Participant

- Ebara Refrigeration Equipment & Systems Co., Ltd.

Outline of GHG Mitigation Activity

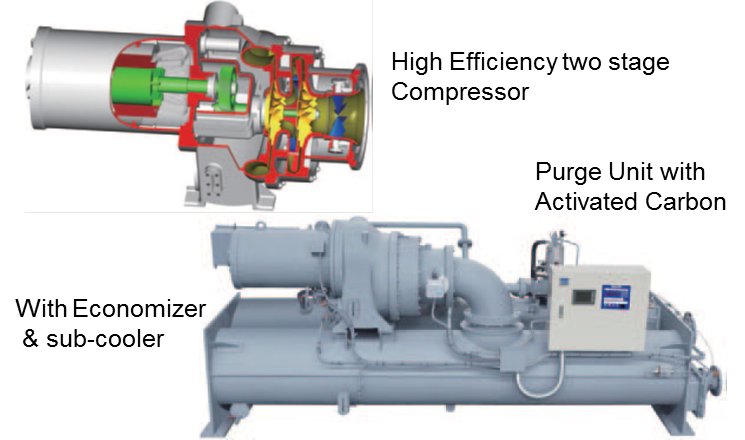

Appropriate process cooling is required for producing high quality food /sugar products. This process cooling consumes large amount of electricity for the operation of chiller. In order to reduce GHG emissions, a high-efficiency chiller is one of the best options. This project introduces high-efficiency centrifugal chillers with ECONOMIZER, refrigerant SUB-COOLER and high efficiency compressor. Also, by applying a purge unit with Activated Carbon, nearly 100% of HFC-245fa refrigerant with zero ODP is recovered for preventing GHG emission.

Expected GHG Emission Reductions

107 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

− (Project CO2 emissions) [tCO2/year]

Reference CO2 emissions: 713.3 [tCO2/year]

Project CO2 emissions: 615.5 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| BD_AM001 Ver2.0 | Energy Saving by Introduction of High Efficiency Centrifugal Chiller | Nippon Koei Co., Ltd. |

Related links

・Carbon Markets Express – Column on 2018.03.15