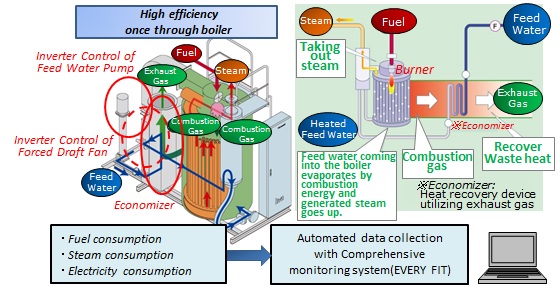

Introduction of High Efficiency Once-through Boiler in Golf Ball Factory

- Representative Participant

- Sumitomo Rubber Industries, Ltd.

Partner Participant: Sumi Rubber Indonesia

Registered

Active

Outline of GHG Mitigation Activity

Expected GHG Emission Reductions

148 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

- (Project CO2 emissions) [tCO2/year]

Reference CO2 emissions :1,631.4 [tCO2/year]

Project CO2 emissions : 1,482.7 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM015 Ver1.0 | Energy Saving by Introduction of High Efficiency Once-through Boiler | Nippon Koei Co., Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID022 | Introduction of High Efficiency Once-through Boiler in Golf Ball Factory | 03 Sep 19 |