Productivity Improvement of Aluminium Ingots Using High Efficiency Furnace System

- Representative Participant

- DAIKI ALUMINIUM INDUSTRY CO., LTD.

Partner Participant: DELTA DAIKI METAL (THAILAND) Co., Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

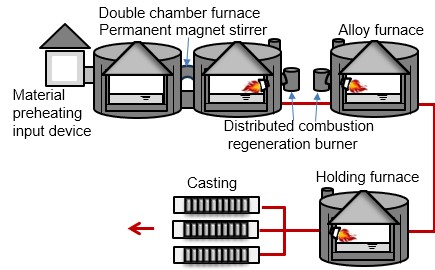

This project introduces a high efficiency furnace system to a new aluminum ingots factory in Rayong province.

The system saves energy consumption and reduces greenhouse gas (GHG) emissions by improving both thermal efficiency and productivity.

It adopts closed type furnaces with distributed combustion regeneration burners and enhances thermal efficiency by reusing waste heat. Additionally, permanent magnet stirring enhances the melting speed.

Expected GHG Emission Reductions

3,859 tCO2-eq./year

= Reference CO2 emissions[tCO2/year]

– Project CO2 emissions[tCO2/year]

・ Reference CO2 emissions[tCO2/year]

= Quantity of the LNG[km3/year] × Emission factor[tCO2/km3] + Quantity of the electricity[MWh/year] × Emission factor[tCO2/MWh]

・ Project CO2 emissions[tCO2/year] = Quantity of the LNG[km3/year] × Emission factor[tCO2/km3] + Quantity of the electricity[MWh/year] × Emission factor[tCO2/MWh]

Site of JCM Project