Introduction of Biomass Co-generation System to Chemical Factory

- Representative Participant

- NIPPON STEEL ENGINEERING CO., LTD.

Partner Participant: NS-OG ENERGY SOLUTIONS (THAILAND) LTD., THAI NIPPON STEEL ENGINEERING & CONSTRUCTION CORPORATION, LTD.

Not registered

Installing

Outline of GHG Mitigation Activity

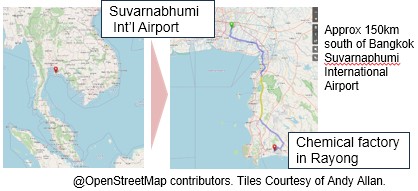

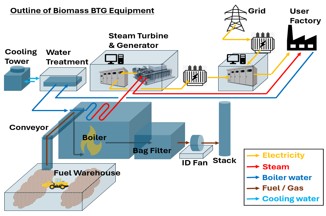

This project introduces biomass co-generation system to a chemical factory in Rayong. The generated electricity and steam are supplied to a chemical factory and another in adjacency.

This project reduces greenhouse gas (GHG) emissions by replacing part of the electricity from the fossil fuel-derived grid power and part of the steam from the fossil fuel burning boiler with power and steam from renewable sources.

Expected GHG Emission Reductions

48,429 tCO2-eq./year

= Reference CO₂ emissions – Project CO₂ emissions

・Reference CO₂ emissions[tCO₂/year]

= (Quantity of the electricity generated by the project)[MWh/year] × Emission factor[tCO₂/MWh] + (Provided steam heat value)[GJ/year] × Emission factor[tCO₂/GJ]

・Project CO₂ emissions[tCO₂/year]

= (CO₂ emissions by on-site consumption of fossil fuel for operating a biomass power plant)[tCO₂/year] + (Transportation activity of solid biomass fuels from collecting sites to a biomass power plant)[GJ/year] × Emission factor[tCO₂/GJ]

Site of JCM Project