Energy Saving Project in the Automotive Glass Manufacturing Process

- Representative Participant

- AGC Inc.

Partner Participant: PT Asahimas Flat Glass Tbk

Not registered

Installing

Outline of GHG Mitigation Activity

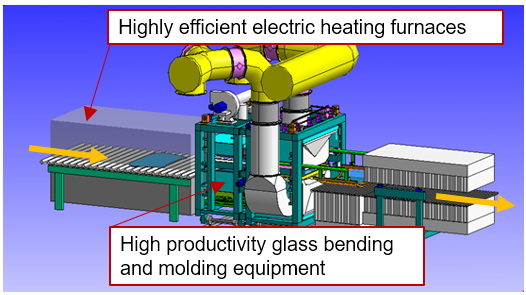

This project introduces highly efficient electric heating furnaces and high productivity glass bending and molding equipment to an automotive glass manufacturing factory in Cikampek City, West Java. The highly efficient electric heating furnaces and high productivity glass bending and molding equipment save energy consumption as well as greenhouse gas (GHG) emissions by reducing electricity consumption and improving productivity.

Expected GHG Emission Reductions

10,715 tCO2-eq./year

= Reference CO2 emissions [tCO2/year]

– Project CO2 emissions [tCO2/year]

・ Reference CO2 emissions [tCO2/year]

= Quantity of the electricity consumed by the reference case [MWh/year]

× Emission factor [tCO2/MWh]

・ Project CO2 emissions [tCO2/year]

= Quantity of the electricity consumed by the project [MWh/year]

× Emission factor [tCO2/MWh]

Site of JCM Project