Introduction of Gas Co-generation System and Absorption Chiller to Motor Parts Factory

- Representative Participant

- DENSO

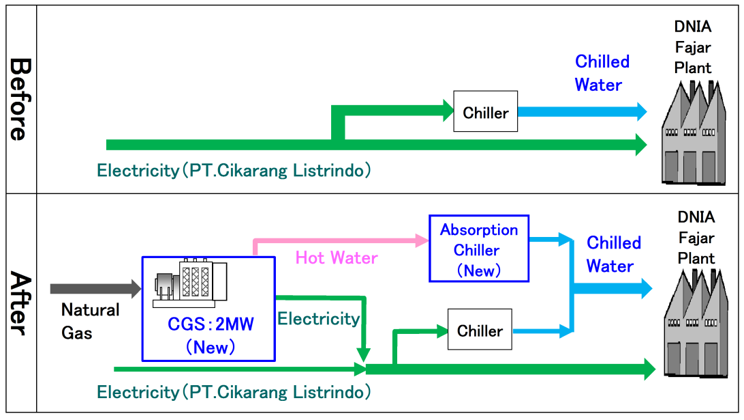

Outline of GHG Mitigation Activity

By introducing co-generation system (gas engine 2,000KW + Absorption Chiller 300RT) in the Motor Parts Factory in Indonesia,

we aim following contribution.

(1) Contribution in the environmental aspect

(Promotion of Energy saving , CO2 reduction) (2) Contribution in the social aspect

(Stable supply by distributed power supply)

(3) Contribution in the technical aspect

(Acquisition of maintenance skill by local staff)

(4) Contribution in the economic aspect

(Influence of business model of on-site co-generation system)

About “(1) Contribution in the environmental aspect”, we can operate co-generation system by high energy efficiency from following reasons, and greatly contribute to energy saving and CO2 reduction. (see right figure)

*1 Suppress of power supply loss by on site generator.

*2 Adoption of the advanced and high efficiency gas engine system

*3 Effective utilization of all waste heat for air-conditioning of plant.

Expected GHG Emission Reductions

4,629 tCO2-eq./year

CO2 reduction of this project

= A : CO2 reduction of electricity + B : CO2 reduction of Natural gas

A : CO2 reduction of electricity

= (Reference usage – Project usage) × Emission electricity coefficient

= (electricity generated + electricity reduction of turbo chiller as reference

by using exhaust heat from co-generation system) ×

Emission electricity coefficient

B : CO2 reduction of Natural gas

= (Reference usage – Project usage) × Emission Natural gas coefficient

= (0 - Natural gas consumption in co-generation system)

× Emission Natural gas coefficient

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM023 Ver1.0 | Installation of gas engine cogeneration system with absorption chiller to supply electricity, heating energy and cooling energy | DENSO CORPORATION |