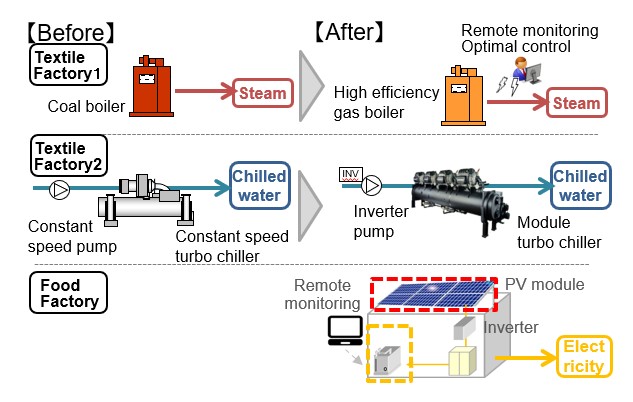

Introduction of High Efficiency Boiler, High Efficiency Chiller, and Solar PV System to Textile Factory and Food Factory

- Representative Participant

- The Kansai Electric Power Company, Incorporated

Outline of GHG Mitigation Activity

High-efficiency gas boilers (actual steam generation amount 5t / h x 2 units) and modular turbo chillers (400RT x 2 units) are installed at two textile factories, respectively. Optimal control of each equipment considering unit control and partial load efficiency save energy when supplying steam or cold water and reduce greenhouse gas (GHG) emissions.

Solar power system (total of about 2.3 MW) is installed on the rooftop of the food factory, and all the generated power is consumed by that factory. Consequently, GHG emissions are reduced.

Expected GHG Emission Reductions

1,914 tCO2-eq./year

= (Reference CO₂ emissions) [tCO2/year]

– (Project CO₂ emissions) [tCO2/year]

Boiler:(Fuel consumption calculated by existing boiler x Emission factor)-(Fuel consumption calculated by new boiler x Emission factor)

Chiller:(Power consumption calculated by existing chiller COP-Power consumption calculated by new chiller COP) x Emission factor

PV :(Reference Power consumption – 0 )

×Emission factor

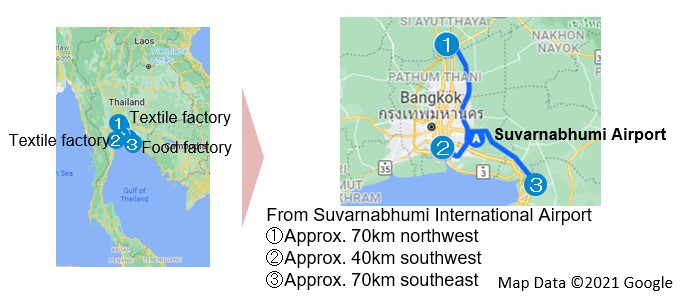

Site of JCM Project