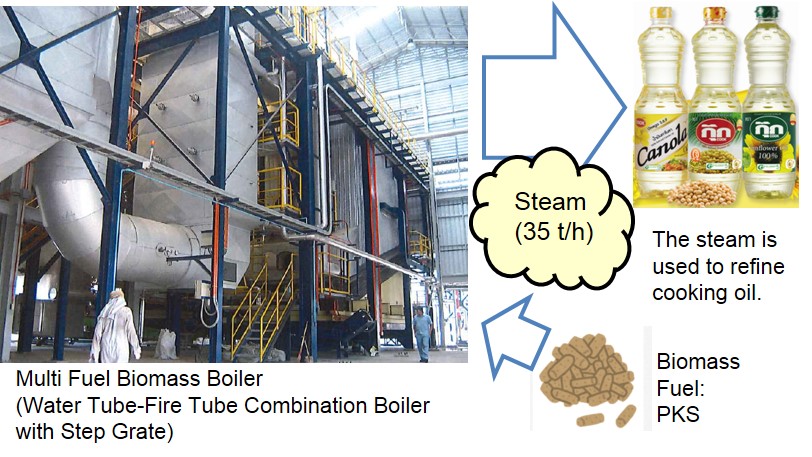

Introduction of Biomass Boiler to Cooking Oil Factory

- Representative Participant

- Tepia Corporation Japan Co., Ltd.

Outline of GHG Mitigation Activity

A biomass boiler with the steam production capacity of 35 tons per hour is installed to a cooking oil factory in Samut Prakan Province. The steam is used in the oil production process.

Palm Kernel Shell (PKS) is used as its biomass fuel, and PKS is procured from multiple suppliers so as to secure the stability of steam production.

Expected GHG Emission Reductions

29,759 tCO2-eq./year

= Reference CO2 emissions (Ry) [tCO2/year]

- Project CO2 Emission (Py) [tCO2/year]

Ry=Reference fuel consumption (RQfy) [t/year]

* Emission Factor (furf) [tCO2/t] + Reference Power consumption (Rqey) [MWh/year]* Emission Factor (gef) [tCO2/MWh]

Py=Project fuel consumption (PQfy) [t/year]

* Emission Factor (fupf) [tCO2/t] + Project Power consumption (Pqey) [MWh/year]* Emission Factor (gef) [tCO2/MWh]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM019 | Installation of Biomass Boiler | Tepia Corporation Japan Co., Ltd. |