Introduction of Biogas Boiler and Waste Heat Recovery System to Beer Factory

- Representative Participant

- Kirin Holdings Company, Ltd.

Partner Participant: Myanmar Brewery Ltd.

Not registered

Active

Outline of GHG Mitigation Activity

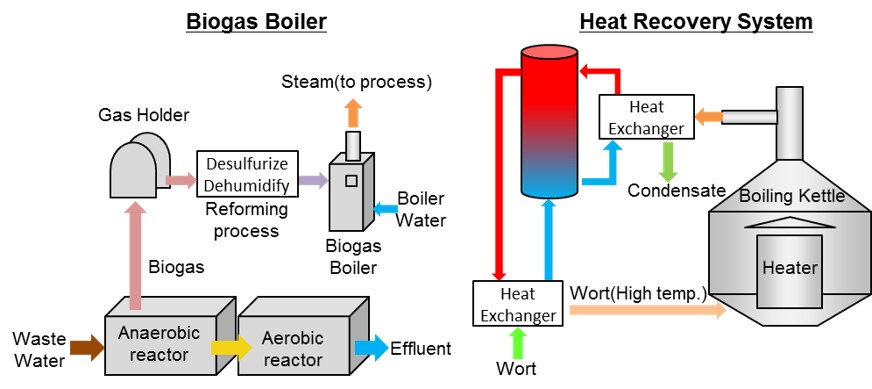

This project introduces high efficiency equipment to a beer factory in Myanmar as its expansion project and reduces energy consumption as well as GHG emission.

Biogas Boiler utilizes biogas from existing anaerobic reactor in the waste water treatment plant. It produces steam which is used in production process.

Heat recovery system captures excess heat from wort boiling process and utilizes it into pre-heating process of wort.

Expected GHG Emission Reductions

3,820 tCO2-eq./year

Heat recovery system: 606 [tCO2/year]

Biogas Boiler: 3,213 [tCO2/year]

CO2 emission reduction

= Energy saving volume × Emission factor

Emission factor:

2.619 [kg-CO2/L-fuel]