Introduction of Energy Saving Refrigerator and Evaporator with Mechanical Vapor Recompression in Amino Acid Producing Plant

- Representative Participant

- KYOWA HAKKO BIO CO. LTD.

Partner Participant: THAI KYOWA BIOTECHNOLOGIES CO.,LTD.

Not registered

Active

Outline of GHG Mitigation Activity

Introduction of energy-saving equipment to amino acid manufacturing plant with the facilities expansion to contribute to the reduction of CO2 emissions.

1)Refrigerator :

Reduce power consumption by introducing high COP turbo refrigerator.

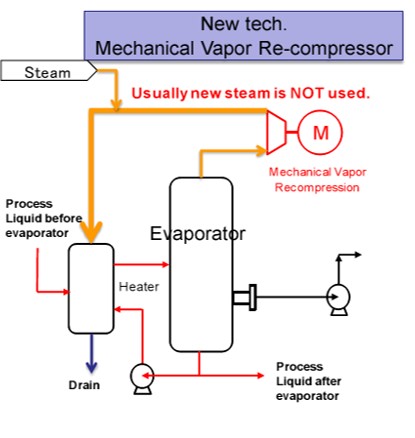

2)Evaporator with Mechanical Vapor Recompression:

Vapor generated in the concentration process of the amino acid solution is re-compressed, and the heat from the vapor is used to as a heat source to reduce the steam.

Expected GHG Emission Reductions

1,527 tCO2-eq./year

1) Refrigerator:

194 [tCO2/year]

2) Evaporator:

1,333 [tCO2/year]

Site of JCM Project

Related photos

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| TH_AM012 Ver1.0 | Energy Saving by Installation of an Evaporator with Mechanical Vapor Recompression | Institute for Global Environmental Strategies |