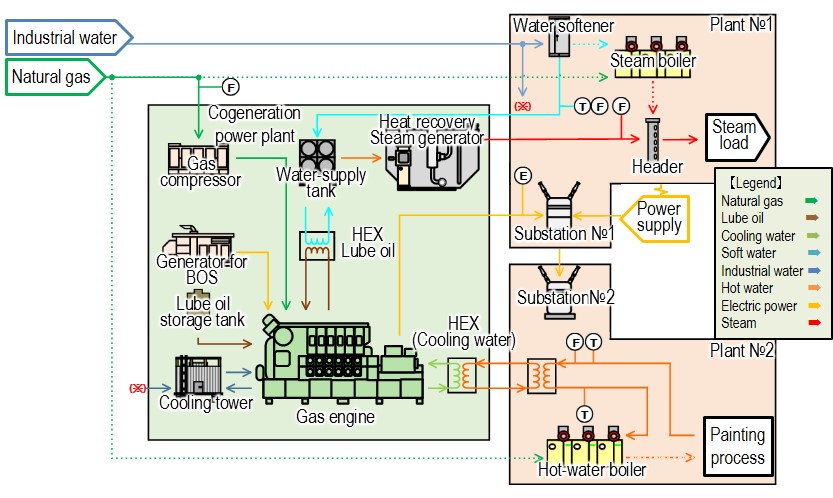

Installation of Gas Co-generation System for Automobile Manufacturing Plant

- Representative Participant

- Toyota Tsusho Corporation

Outline of GHG Mitigation Activity

The purpose of this project is to reduce energy consumption and CO2 emission by installing a gas co-generation system. This system adopts a high efficiency gas-engine and heat recovery system to generate steam and hot water.

This project contributes to the reduction of energy consumption at coal fired power generation prevailed in Indonesia, and to the reduction of GHG and air pollutant emissions.

Expected GHG Emission Reductions

21,793 tCO2-eq./year

←Reference emissions - Project emissions

① Reference emissions =(Quantity of available electricity generated by gas-engine × CO2 emission factor of the grid) +(Amount of heat recovery ÷ Efficiency of the reference equipment ×CO2 emission factor of fuel used by the reference equipment )

② Project emissions =Natural gas consumption of gas-engine × Heating value of natural gas × CO2 emission factor of natural gas

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM016 Ver1.0 | Installation of gas engine cogeneration system to supply electricity and heat to facility | Institute for Global Environmental Strategies |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID019 | Installation of gas engine cogeneration system to supply electricity and heat to the vehicle manufacturing factory of PT. Toyota Motor Manufacturing Indonesia | 09 May 19 |