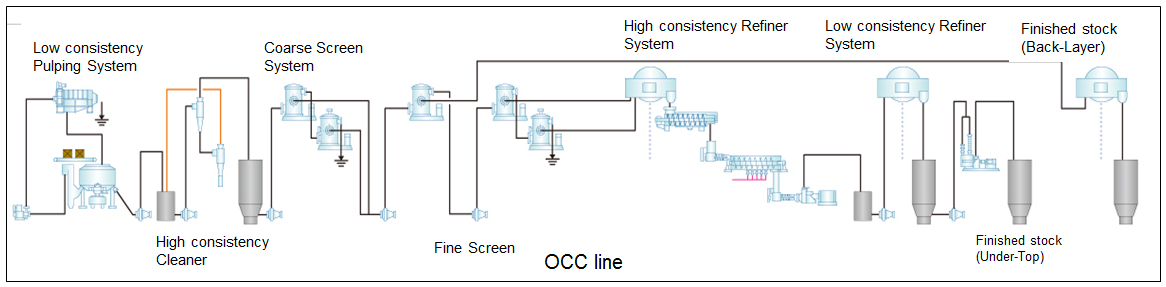

Introduction of High Efficient Old Corrugated Cartons Process at Paper Factory

- Representative Participant

- Kanematsu Corporation

Partner Participant: PT Fajar Surya Wisesa Tbk.

Registered

Credit issued

Active

Outline of GHG Mitigation Activity

This project aims to achieve electricity usage reduction per ton produced (by about 10 %) by introducing a Japanese high-efficient system to the OCC line for Fajar Paper, thereby contributing to CO2 reduction.

The OCC line is a process to prepare clean raw materials containing dissolved paper fibers by mixing used corrugated board into water for defiberization and removing foreign substances. Since a large amount of material (water) is used, electricity is significantly consumed to power motors.

Expected GHG Emission Reductions

19,011 tCO2-eq./year

= (Reference CO2 emissions) [tCO2/year]

− (Project CO2 emissions) [tCO2/year]

Reference CO2 emissions: 52,578.0 [tCO2/year]

Project CO2 emissions: 33,566.4 [tCO2/year]

Site of JCM Project

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM012 Ver1.0 | Reduction of Energy Consumption by Introducing an Energy-Efficient Old Corrugated Carton Processing System into a Cardboard Factory | Nomura Research Institute, Ltd. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID011 | Energy ConsumReduction of ption by Introducing an Energy-Efficient Waste Paper Processing System into a Packaging Paper Factory in Bekasi, West Java | 22 Dec 17 |

Issuance of credits

| Reference No. | Monitoring Period | Date of JC decision on notification | Amounts of Credits Issued | |

|---|---|---|---|---|

| - | ID011 | 01 Jul 17 - 31 Aug 18 | 10 Jan 20 | 16,177 |