Energy Saving through Introduction of Regenerative Burners to the Aluminum Holding Furnace of the Automotive Components

- Representative Participant

- Toyotsu Machinary Corporation

Outline of GHG Mitigation Activity

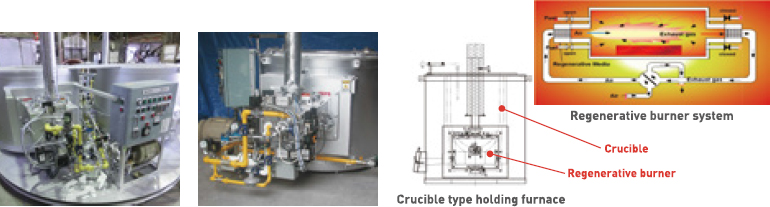

Replacing a conventional burner with a high-efficiency regenerative burner for an aluminum holding furnace improves energy saving and reduces GHG emissions. YPMI has an aluminum wheel die casting line with 11 crucible type holding furnaces. Local furnace manufacturer PT. Matahari replaces and modifies the furnaces supervised by the branch of Japanese furnace manufacturer Hokuriku Techno. PT. Matahari acquires sophisticated furnace design and manufacturing knowhow of regenerative burner furnaces and their tuning/maintenance techniques.

Expected GHG Emission Reductions

98 tCO2-eq./year

Site of JCM Project

Karawang, West Java, Indonesia

JCM Methodology

| Methodology No. | Title | Methodology Proponent |

|---|---|---|

| ID_AM009 Ver3.0 | Replacement of conventional burners with regenerative burners for aluminum holding furnaces | Toyotsu Machinery Corporation, Mizuho Information & Research Institute, Inc. |

Progress

JCM Project Registration

| Reference No. | Project Title | Registration Date |

|---|---|---|

| ID010 | Energy saving through introduction of Regenerative Burners for aluminum holding furnaces of the automotive components manufacture in the Republic of Indonesia | 30 Mar 20 |

Related Documents

・Seminar on the JCM Project Implementation in Indonesia (2017)

Energy Saving through Introduction of Regenerative Burners to the Aluminum Holding Furnace of the Automotive Components Manufacturer – Mr. Masashi Ikuta, TOYOTSU MACHINARY CORPORATION